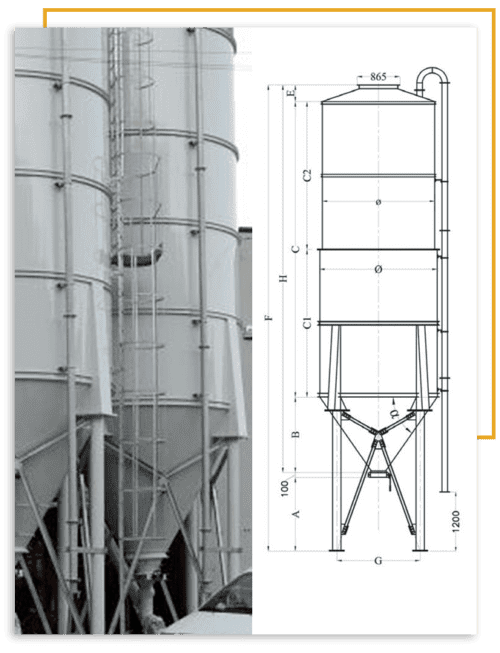

- Robust storage solutions from 21m³ to 43m³ capacities.

- Secure assembly with multiple ferrules.

- Dimensions include Ø2100 diameter and heights up to 15740mm.

- Ideal for indoor and outdoor industrial storage.

| Codice | Capacità m3 | N° virole | ø | ø minore | A | B | C | C1 | C2 | E | H | F | G |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SML 21-21 | 21 | 4 | 2100 | 2000 | 1500 | 1300 | 6000 | 3000 | 3000 | 240 | 7540 | 9140 | 1500 |

| SML 21-30 | 30 | 6 | 2100 | 2000 | 1500 | 1300 | 8600 | 4300 | 4300 | 240 | 10140 | 11740 | 1500 |

| SML 21-37 | 37 | 7 | 2100 | 2000 | 1500 | 1300 | 10500 | 6000 | 4500 | 240 | 12040 | 13640 | 1500 |

| SML 21-43 | 43 | 8 | 2100 | 2000 | 1500 | 1300 | 12600 | 6300 | 6300 | 240 | 14140 | 15740 | 1500 |