- Massive 420L hopper

- Fork pockets to facilitate moving machine

- Heavy duty construction

- Designed to minimise operator fatigue

- Can be operated manually or automatically

- Drive motor 1.85kW

- Hopper beater motor 1.1kW

- Cycle rate 8 secs

- Weigh table capacity 250kg

- Vibrators (2) 100mve

Batchcrete International – Quality Concrete Batching and Mixing Equipment

Welcome to Batchcrete International, your trusted partner for exceptional concrete batching and mixing solutions in Australia. We specialise in delivering a broad selection of concrete batching and mixing equipment that is designed to cater to the requirements of diverse projects, both large and small.

Our products are engineered for reliability and efficiency, ensuring they are cost-effective and easily transportable. Whether you’re gearing up for a major commercial project or a small residential job, our equipment is designed to minimize downtime and streamline your operations.

Products Available

At Batchcrete, we offer a wide array of concrete equipment designed for various production needs. Each product is built to enhance your operational efficiency and quality, from automated systems to specialised machines.

-

Automated Batching Systems

Discover our range of automated batching systems designed to streamline your concrete production process, ensuring precision and efficiency at every step.

Automated Dosing Machine: Equipped with a massive 420L hopper, this machine is tailored to reduce operator fatigue and can be operated manually or automatically. It includes features like fork pockets for easy mobility and is built for heavy-duty use.

Automated Mould Feeding Line: This mobile setup is easy to adjust and can be customised to various lengths between 7 – 8 meters, ensuring seamless integration into your production line.

-

Vibrating Tables and Mould Machines

Explore our selection of vibrating tables and mould machines engineered to enhance the quality and consistency of your concrete products through optimal compaction and shaping.

Batchcrete Vibrating Table: Constructed with robust steel and a powerful 400 series vibrator motor positioned directly below the table, this equipment ensures optimal compaction of concrete, essential for quality constructions.

De-moulding Machines: These machines are crucial for efficiently removing pavers from their moulds, which not only speeds up the production process but also prevents manual strain and potential injuries.

-

Specialized Manufacturing Equipment

Unlock new possibilities with our specialised manufacturing equipment, tailored to meet the unique requirements of your projects and maximize your production capabilities.

Block Making Machine – T & P Bloc 30000: This versatile machine offers hydraulic compression and an adjustable working area, suitable for producing a variety of block sizes and types under different pressures.

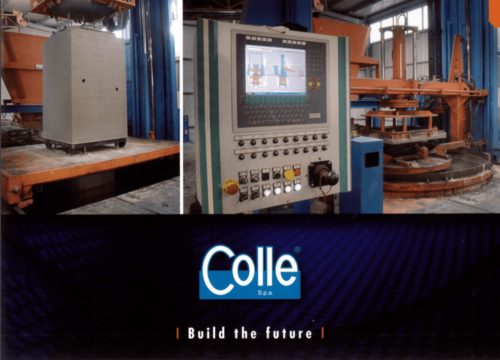

Colle Series Machines: Our Colle series encompasses several machines like the Bimatic and Rotovibromatic, each designed for specific production needs, ensuring flexibility and high-quality output.

Applications of Our Equipment

Batchcrete’s equipment is versatile and can be used in a variety of industries, ranging from construction to manufacturing. Our machines are designed to meet the rigorous demands of any site or factory.

- Construction Sites: Our machines are perfect for both high-rise buildings and residential projects, providing reliability and consistency in concrete production.

- Manufacturing Facilities: Designed for high output and continuous operation, our equipment is ideal for facilities producing concrete products like blocks, pipes, and pavers.

- Specialty Projects: We also provide solutions for more specialised needs, such as customisable moulds for unique concrete products, ensuring you have the right tools for any project.

Why Choose Batchcrete?

Choosing Batchcrete means opting for excellence in concrete equipment manufacturing. Our commitment to quality, customer service, and innovation sets us apart in the industry.

-

Customisation

We understand that each project is unique, and our equipment can be customised to meet the exact needs of your operations. Whether it’s adjusting the capacity, size, or specific operational features, we work closely with you to tailor our equipment to your project’s requirements.

-

Quality and Durability

Our machines are constructed with high-quality materials and advanced technology to ensure longevity and optimal performance in harsh environments. Each piece of equipment undergoes rigorous testing and quality assurance processes, guaranteeing durability and reliability under all conditions.

-

Support and Service

Our comprehensive after-sales support includes a full warranty, maintenance services, and access to our expert service team. We provide a robust support system to ensure you receive timely assistance and ongoing maintenance to keep your equipment operating at peak performance.

-

Cost-Effective Solutions

We help you optimise your operations with machinery that maximises productivity and reduces operational costs, making our equipment a smart investment. Our cost-effective solutions are designed to deliver high performance without breaking the bank, ensuring a solid return on your investment.

Frequently Asked Questions (FAQs)

Before purchasing, our customers often have questions about our products and services. Here are some of the most common inquiries we get, along with detailed answers.

Q1: Can I customise the machinery to fit specific project needs?

Absolutely, customisation is one of our specialties. Whether it’s adjusting the capacity, size, or specific operational features, we work closely with you to tailor our equipment to your project’s requirements.

Q2: What type of support can I expect after purchasing equipment?

We provide a robust support system, including full service backup, routine maintenance, and immediate assistance for any operational challenges you might face.

Q3: How does Batchcrete ensure the quality of their equipment?

Each piece of equipment is subjected to rigorous testing and quality assurance processes. We use only the best materials and the latest technologies to ensure each product meets the highest standards of quality and reliability.

Q4: Are there financing options available for purchasing Batchcrete equipment?

Yes, we offer flexible financing options designed to ease the financial burden of acquiring new equipment. Our team can provide detailed information to help you find the best financing solution.

Q5: How can I see the equipment in action before making a purchase?

We encourage potential customers to visit our facilities for a live demonstration, or you can view detailed demos and read testimonials on our website to gauge the effectiveness of our machinery in real-world scenarios.

Connect With Us

We invite you to explore the advanced capabilities of our concrete batching and mixing solutions at Batchcrete. Whether you need a customized setup or a standard solution, we are here to enhance your production efficiency. Make a product enquiry or call us at 1800-739-006 to discuss your needs with our experts today!

-

Features and Benefits

Features and Benefits -

Features and Benefits

Features and Benefits- Fully warranted with service support backup.

- Mobile set-up and easy readjusting.

- Dosing lines built to suit and generally range between 7 – 8 metres in length.

-

Features and Benefits

Features and Benefits- Strong steel construction

- Built with provision to accept fork tynes, making both upper and lower sections mobile.

- Dosing controlled by PLC

-

Features and Benefits

Features and Benefits- Product height: 20-35 cm

- Working pressure: 100/150 bar

- Compression: Hydraulic

- Working area: 110 x 50cm

- Power: 18.5 kW

-

Features and Benefits

Features and Benefits- The fully automatic work cycle and the electronic control system with the Vicom PC ensures the machine is easily managed. It also controls the quality and speed of the production process.

-

Features and Benefits

Features and Benefits- The Rotovibromatic can be modified for specific requirements with tools that diversify production and makes production totally automatic, thus providing benefits such as:

- Reduction in labour requirements

- Improved production speeds and faster mould changes.

- The Rotovibromatic can be modified for specific requirements with tools that diversify production and makes production totally automatic, thus providing benefits such as:

-

Features and Benefits

Features and Benefits- Over 25 different products which can be cast.

- Cast can be made to suit specific requirements

- Over 25 different products which can be cast.

- Cast can be made to suit specific requirements

-

Features and Benefits

Features and Benefits- Features that make the Vibromatic 3000 an excellent choice are:

- Easy installation

- Functions that smooth the inner surface of the pipe

- Mechanical adjustment of the vibrators for stroke-force and the speed of the vibrators by means of electric inverter

- The automatic feeding of the base pallets

- Easy access to the hopper for inspection and cleaning operations

- Features that make the Vibromatic 3000 an excellent choice are:

-

Features and Benefits

Features and Benefits- A special feeding belt makes sure that moulds of any shape are equally filled.

- The machines desk height can be adjusted in order to produce elements of different dimensions.

- Over 29 different products which can be cast

-

Features and Benefits

Features and Benefits- Over 23 different products which can be cast.

- Cast can be made to suit specific requirements

- Suitable for both indoor or outdoor use.

-

Applications

Applications- The de-moulding machine extracted pavers from moulds with maximum efficiency

- The de-moulder is a vital piece of equipment that alleviates double handling and improves on productivity once the pavers are cured

- Assists with the prevention of repetitive strains.