Concrete Mixers

Concrete Mixers

Concrete Mixers are reliable machines designed to mix concrete efficiently for construction projects.

On-site concrete mixing can lead to uneven consistency. Our concrete mixers provide stable, high-performance mixing to produce a flawless, uniform batch every time, allowing you to stay on track.

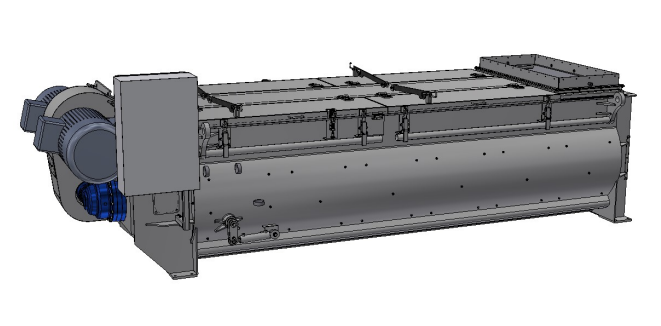

Komplet XC500 – Twin Shaft Compulsory Mixer

Description

- Twin shafts for efficient mixing.

- Output: 190 m³/hour (soft cement) and 456 tons/hour (vibrated cement).

- Durable with anti-wear materials.

- Powered by two 55 kW electric motors.

- Compatible with batching plants, automatic aggregate loading.

- Counter-rotating spiral motion for better mixing.

- Replaceable parts: mixing blades and linings.

- Safety features: guards, interlocks, and belt protection covers.

- Ideal for large-scale projects like road foundations and dam fillings.

Mixer Buckets

- Less manual handling.

- Low cost mobile mixing solution

- Rotating mixing arm produces a high quality mix.

- Fully enclosed gearbox drive

- Electronic chute opening, from inside of cab

- Mixer buckets are ideal for low lying concrete work

- Mixing bucket yields approximately .2 to .6m³

Mixers- Self Loading

- Hoppper loading with mini loader or skidsteer, limits manual handling

- Available in Diesel or Electric

- Steel Collar to prevent spillage

- Very mobile and easily transported

- Pneumatic Tires

- Water tank with level indicator

- Opposite direction rotation for discharge

Screed Mixer

- Available in three sizes to suit any job

- Safety cut out, shuts down mixing if grille is opened

- Lightweight for ease of loading and transport

- Bag opener allows for mess free addition of product

- Dispense chute and deep pan allow for mess free operation

- Water supply connection installed.

- Adjustable legs for levelling on unstable ground

Screed Mixer- Large

- Available in either petrol or electric motors

- Single shaft turbo mixing action

- Multiple mixing arms and prepare cement in quick fashion

- A guard over the outlet prevents access to the mixing zone

- Trailer mounted: Easily moved from one location to the next

- The mixer will stop if the cover is open

- Water supply connection installed.

- Tank protection cover enables loading of mix components without accessing the mixing zone.

Sicoma Lab Mixer MP75/50

- Large loading opening

- Radiant plates with thermal sensors

- Tip limit switch

- Hydraulic tilt function for discharge of product

- Fully enclosed control cabinet.

Sicoma MAO – Twin Shaft Single Batching System

- Liner plates and mixing plates in Ni-Hard Cast Iron

- Mixing arms in cast iron, bolted to shaft

- High top cover with inspection hatches and ports

- Inspection platform and stairs

- Wiring of all auxiliary devices to an IP55 Junction Box

- Alarm box with related sensors and probes.

- Auto grease lubrication system with electric pump and sequential distributor.

- Wrench kit for the mixer maintenance

- Safety key lock for accident prevention

Sicoma MAO/C – Twin Shaft Continuous Mixers

- Ni-Hard Cast Iron liner plates and mixing plates

- Cast iron mixing arms, securely bolted to the shaft

- High top cover with inspection hatches and access ports

- Inspection platform with stairs

- Auxiliary device wiring connected to an IP55 Junction Box

- Alarm box with sensors and probes for monitoring

- Automatic grease lubrication system with electric pump and sequential distributor

- Wrench kit provided for mixer maintenance

- Safety key lock to prevent accidents

Sicoma Planetary Mixers

- Huge double horizontal shock resistant gearbox.

- Gears immersed in an oil bath

- Gearbox carries 5-year or 10000 hour warranty.

- Strong mixing arms with blades made from NY-hard iron, 550 HB

- 15mm NY-hard cast iron floor and wall lining

- Up to 4 swing out discharge sector doors

- Doors are either hydraulically, pneumatically or manually operated.

- Hollow central shaft supports washout jets beneath the rotating arms.

- High-pressure pump creates a water tornado, reducing wash-up time by 80%.

- Compliant with ISO 9001:2000

Description

Tired of Bad Concrete Mixes? Get a Perfect Batch, Every Time

One bad batch of concrete can ruin your day. This creates weak spots and cracks, wastes valuable material, and puts your project behind schedule and over budget. In truth, how you mix your concrete matters.

A poor mix can make concrete up to 30% weaker. That’s a serious risk to the quality and safety of your work.

You need a strong, smooth, and consistent mix for every pour. Our concrete mixers are built to solve this problem. They are reliable machines that give you a flawless, uniform batch every single time, so you can build with confidence.

The Right Concrete Mixing Equipment for Your Project

Every job is unique, so we offer a range of mixers to match your needs. We have options for sale and for rent.

- For Moving Around a Site: Our Mixer Buckets and Self-Loading Mixers are perfect as a portable concrete mixer. Perfect for repairs, tight spots, and jobs requiring mobility.

- For Smooth Floors: Our Screed Mixers come in standard and large sizes and provide a perfectly blended screed for flawless floors and surfaces.

- For Heavy-Duty Performance: When the job demands power and precision, our Sicoma range is the answer. We have Sicoma Planetary Mixers, Sicoma MAO – Twin Shaft systems, and even the Sicoma Lab Mixer.

- For Massive Projects: For jobs that need non-stop concrete, our Sicoma MAO/C – Twin Shaft Continuous Mixers keep the material flowing.

Quick Guide to Using Your Concrete Mixer

Understanding how concrete mixer works is pretty simple. The drum spins around and the blades inside lift your materials up and drop them back down. This keeps mixing everything evenly.

So, how do you mix concrete in a mixer? Start by adding half your water first. Then put in your cement, sand, and gravel. Finally, add the rest of the water while it’s running.

Most people ask how long should you mix concrete in a mixer. The answer is about 3 to 5 minutes after everything is in. You’ll see when it looks smooth and even.

Finally, knowing how to clean concrete mixer equipment is really important. Do it straight after you finish. Add water and gravel, let it run for a minute, then rinse everything out with a hose. That’s it.

Why a Good Mixer Makes All the Difference

A quality mixer is a true game-changer on any job site. Here’s how it helps you:

- Build Stronger: Get strong, durable concrete without any weak spots. This means your work will last longer and be much safer.

- Save Time: Our machines mix fast and efficiently. Your crew can spend less time mixing and more time building.

- Waste Less Money: A perfect mix means you don’t throw away expensive materials. This saves you money on every single project.

- Easy to Use: Our mixers are straightforward and built for real-world use. They are simple to operate and maintain, so you can focus on the job.

Concrete Mixer Hire or Sale? We Make It Easy

Whether you want to own or just borrow, we’ve got you covered.

Looking to buy concrete mixer? We have a huge range of new concrete mixer for sale models to choose from. You can find the perfect Cement Concrete Mixer for Sale for your business, and we even offer quality used concrete mixer for sale options to fit your budget.

Just need a machine for a short time? Our concrete mixer hire service is simple and flexible. A concrete mixer rental is the perfect solution for a specific job.

As your local experts, we are the number one choice for a cement mixer for sale in Perth and Parth WA.

Frequently Asked Questions

1. For what do you use your mixers?

Our mixers are used for everything, from foundations and driveways to large infrastructure projects involving bridges and tunnels. Whether one needs concrete for a small repair or a massive building, we have just the right machine that fits.

2. Can I use these mixers for small jobs?

Yes, absolutely. Our Mixer Buckets are perfect for smaller tasks like fence posts, patios, or repair work. They give you a professional-quality mix without needing a giant machine.

3. Is it better to rent or buy a mixer?

Concrete mixer rental is a great choice for a single project or if you want to avoid storage and maintenance. If you use concrete regularly, it’s usually more cost-effective in the long run to buy a concrete mixer.

4. What kind of maintenance do the mixers need?

The most important thing is to clean the mixer after every use, so concrete does not harden inside. Besides that, they only require basic checks on oil and moving parts, as would any other equipment.

Why Choose Batchcrete International?

We understand concrete, and we know how important it is to your project’s success. We provide reliable machines that eliminate guesswork and help you work faster and smarter.

Ready to get a perfect mix, every time? Check out our range of concrete mixers or talk to our friendly team today to find the right solution for you.